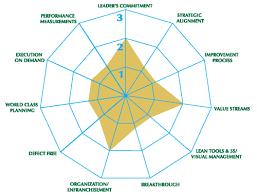

End to end manufacturing process and production workflow assessment report, with focus areas of opportunity.

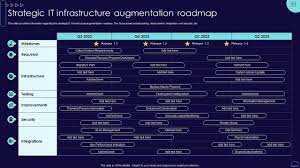

Agile project deployment timeline driving incremental benefits and continuous improvement.

Enterprise architecture to enable digital augmentation holistic data analytics AI and information collaboration to empower staff with knowledge to make informed decisions.

Focus on a known problem: – Old equipment, process variability, labour availability, training, environmental / health issues, contract labour, product quality, material variability. Target something that’s already a big issue.

Experienced across broad range and maturity of industrial automation and control systems. Understanding the value and transformation that Industry 4 technologies can deliver. Good understanding of integration challenges.

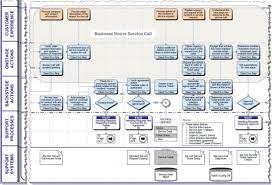

Worked with many MES applications from many vendors – deep knowledge supportinng implementation and integration with business systems and shop floor and laboratory equipment.

Eperience mapping Master Data and workflows to ensure seamless resilient collaboration between business and manufacturing systems.

Holistic augmentation, integration and cotextualisation of data across the breadth of networking and data mapping, to create client focussed Digital Twins underpinned by a unified namespace.

20+ years experience delivering manufacturing execution, analysis and ERP / PLM integration projects working with many competing vendor software applications.

Holistic material transformation models underpinned by RAMI 4 Industry 4 reference modelling and Digital Twin techniques to drive collaboration between systems, processes and people. Then deploying these models into an enduring, agile collaborative digital ecosystem to support the continuous plant and IT landscape churn and evolution.

Pharmaceutical

Projects:

Aerospace

Automotive

Food and Beverage

Electronics

Chemicals